Hazardous Substance Control Bureau (HSCB) announced an important document regarding CBI request on November 9th. The notice mentioned that DIW will not receive any CBI application document from December 1st when inconsistencies will be made in trade name for SDS, scan data etc. which were sent to DIW.

INFORMATION

An IMPORTANT NOTICE on CBI REQUEST, ISSUED by DIW, THAILAND.

TWO SEMINARS ON HAZARDOUS SUBSTANCE ACT, THAILAND IN SEPTEMBER

Key officers of Hazardous Substance Control Bureau (HSCB), Department of Industrial Works (DIW), the Ministry of Industry, Thailand delivered some important presentations concerning about the introduction on the progress of the existing chemicals inventory system, called ‘Preliminary Inventory Data Base (PIDB)’ including procedures on notification system for substances / products during September 7th and 8th in Bangkok.

September 8th

Half day seminar, held by DIW: Criteria and Procedures of New Hazardous Substance Law and Amendment of mercury and its derivatives management’, held on September 8th at DIW, Bangkok.

You are able to access the existing chemicals on the HSCB’s web site by inputting;

1) CAS number for single substances or

2) Company name and trade mane for each product.

An officer of HSCB realized that it was challenging for researchers to search data from the PIDB through inputting company name and trade mane. The PIDB requires correctness and consistencies for each company name and trade mane.

Note: PIDB system rejects to access the data base when huge number of accesses will be occurred due to limited server capacity and / or security issues in DIW buildings. HSCB acknowledges the problem and countermeasures will be implemented soon or under construction.

September 7th

One day seminar with Ms. Somsri, Bureau Director for HSCB, held by a private company entitled 'Dangrenous Goods Risk Management 2016, Are you a risk lover?' in Bangkok.

Major topics;

- Update Hazardous Substance Act

- Update Hazardous Substance Single Submission (HSSS)

- Notification of Ministry of Industry, Subject Hazardous substance list 2015

- Update expenses, fines of customs

SEMINAR ON HAZARDOUS SUBSTANCE SINGLE SUBMISSION (HSSS), HOSTED BY DIW.

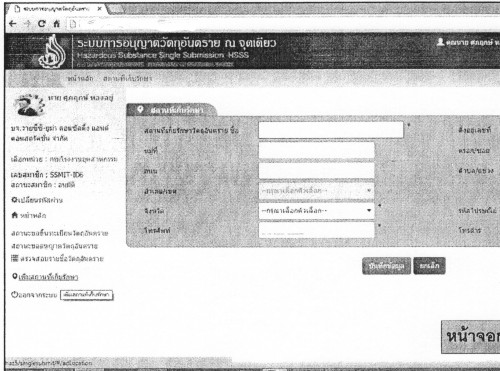

Seminar on Hazardous Substance Single Submission (HSSS) was held at Department of Industrial Works (DIW), Thailand on August 24th, inviting around two hundreds of Audiences who were working for industrial sectors.

The seminar was hosted by DIW to introduce a web based application system which will enable importers and manufactures to submit substances information which were classified as hazardous substance type 2 and type 3. An officers in DIW explained the details of the system.

A part of material for HSSS

On the other hand no announcement was made on the date of services commencement for the HSSS.

PRESSURES IN THAILAND BY GERMAN GOVERNMENT TO ---

Just a reference in understanding amendment procedures on regulations in Thailand.

Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH, on behalf of the German Federal Ministry of Economic Affairs and Energy (BMWi), published a position paper entitled’ PV ROOFTOP DEVELOPMENT IN THAILAND Analysis of Regulations and Challenges in March 2015.

They pointed out issues of the Factory Act 1992, managed by the Department of Industrial Works, the Ministry of Industry, which was a barrier to prevent from installation of solar power system.

The report strongly claimed that it is advised to define clear requirements, procedures and deadlines for obtaining the factory operation license. The information should be made publically available and equally known to all involved stakeholders. In addition, procedures, requirements and deadlines should be applied transparently and uniformly by the competent authorities.

You are able to download the report at;

http://www.thai-german-cooperation.info/download/20140408_pdp_th_report_pv_regulations.pdf

Some remarkable improvements have been made thanks to the position paper.

It seems to me that procedures of amendment for Hazardous Substance Act should be followed the successful path of the Factory Act.

ABSOLUTELY IMPOSSIBLE TO SECURE CBI IN THAILAND

Figure Notification procedure on hazardous substances information

HSCB; Hazardous Substance Control Bureau, DIW: the Department of Industrial Works

![]() cbi july 31.pdf (0.33MB)

cbi july 31.pdf (0.33MB)

- Importers in Thailand have still been key players in the notification on hazardous substance to HSCB, DIW Thailand.

- Most of the notifications on existing chemicals have been made by importers of the products, reflecting upon direction by HSCB.

- On the other hand, some importers have had tough time in getting CBI from manufacturers and are not able to apply useful products for importation to Thailand.

- Some Manufacturers, located on the outside of Thailand, strongly claimed that confidential business information (CBI) would not be secured in this notification procedure.

- Absolutely, the notification procedures do not prevent CBI leak from importers to other manufacturers.

- Copy of original products might be released all over the world.

- We reallize that almost all legal processes in Hazardous Substance Act were absolutely not clear.

- How to address it?